Polishing equipment

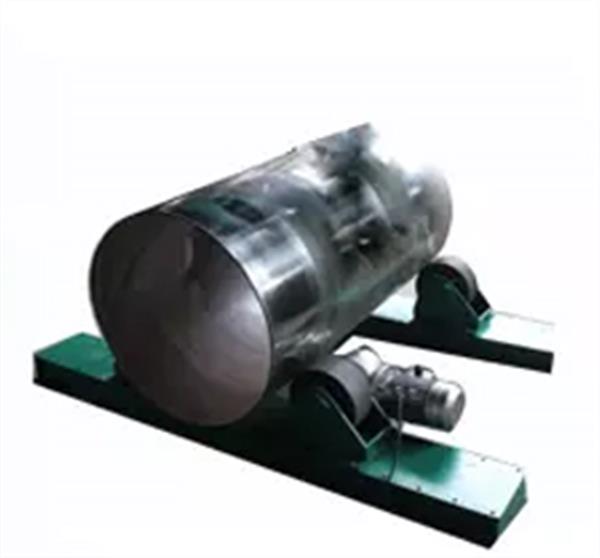

Stainless Steel Tank Polishing & Dished End Buffing Machine

Universal Stainless Steel Tank polishing machine and dished end buffing machine is mainly used to grind the inner and outer surfaces of large and medium-sized industrial tanks, the inner and outer surfaces of the cylindrical cylinder, and the surface of the rotary surface and the surface of the head. It is an ideal equipment for automatic polishing and polishing of the surface of boilers, stainless steel containers, pipes and similar large and medium-sized workpieces.

The lifting and lowering of the working arm adopts a worm-worm reducer and a sprocket, and a chain mechanism is used for transmission. The use of counterweights ensures smooth lifting operation, low vibration and not easy to mechanical wear. Because the reducer has a certain self-locking property, and the lifting motor adopts a brake motor, the working arm can be lifted to any position to stop and lock.

The working arm telescopic adopts worm-worm gear transmission, gear rack walking, high precision and good stability. The speed adjustment is realized by the frequency converter, which has the advantages of smooth transmission and large variable speed range.

The Universal Stainless Steel Tank polishing machine and dished end buffing machine adopts constant pressure floating grinding head throughout the whole process, and the workpiece rotation and lateral feed are frequency conversion stepless speed regulation, which further improves work efficiency. Suitable polishing materials are Thousand Impeller Wheel, Cloth Wheel, Hemp Wheel, and Nylon Wheel can realize the surface Brushed.

It adopts frequency conversion control, adjustable speed and high efficiency. At the same time, it produces head polishing machine, natural gas bottle polishing machine, water supply tank polishing machine, pressure vessel polishing machine, etc. It is mainly used to grind the inner and outer surfaces of large and medium-sized industrial tanks, cylindrical cylinders, curved surfaces and head surfaces. It is an ideal equipment for automatic polishing and polishing of the surface of boilers, stainless steel containers, pipes and similar large and medium-sized workpieces.

FAQ

Q: Do you have stock for Universal Stainless Steel Tank polishing machine and dished end buffing machine?

A: Actually most of our machines are customized.For some common types we have.

Q:What is the product warranty for Universal Stainless Steel Tank polishing machine and dished end buffing machine?

A:We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

Q:When can I get the quotation?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management, WhatsApp, or call us directly.

Q:How to control product quality for Universal Stainless Steel Tank polishing machine and dished end buffing machine?

A:We always attach great importance to product quality. Before leaving the factory, it will be fully aged and debugged. And we always adhere to the principle of "providing customers with better quality, better price and better service.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China