News

Production solution for wheelbarrow production line

This article describes the production solution of the wheelbarrow production line, which can be used to produce the wheelbarrow. The wheelbarrow is mainly used in farms, construction sites, gardens, etc. It is cheap and easy to use. .

How to make a wheelbarrow?

The main equipment is

Pipe cutting machine

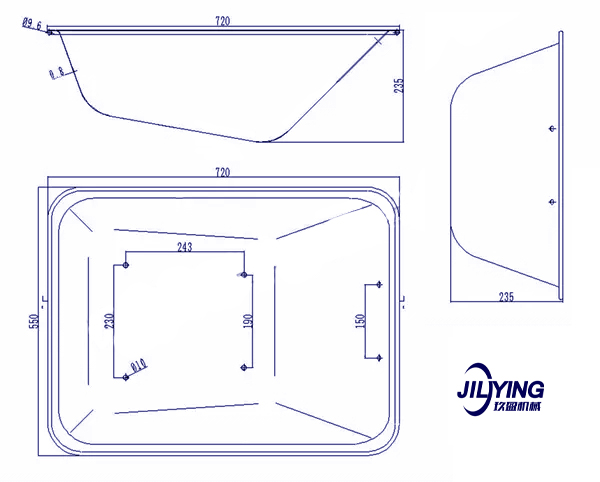

If you want to make a wheelbarrow, you need to understand the structure of a wheelbarrow, as shown in the figure.

Key information to confirm

1. The material, size and thickness of the body of the wheelbarrow

2. The material, diameter and thickness of the pipe part of the wheelbarrow

3. Whether a logo is required, and the size and position of the logo

Brief description of production process

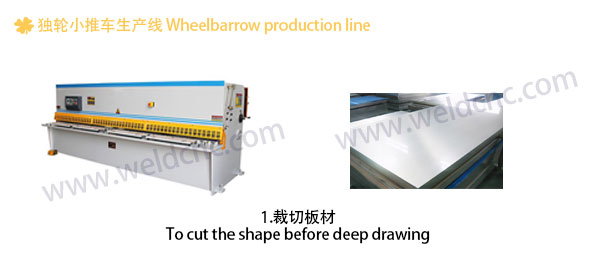

1. Cutting: Use the shearing machine to cut the plate into a suitable size. The model of the shearing machine can be QC11Y and QC12Y general-purpose shearing machine. This type of shearing machine has mature technology, convenient and fast operation, simple maintenance and high production efficiency. , and a variety of sizes are available, reducing cutting errors and saving materials to the greatest extent.

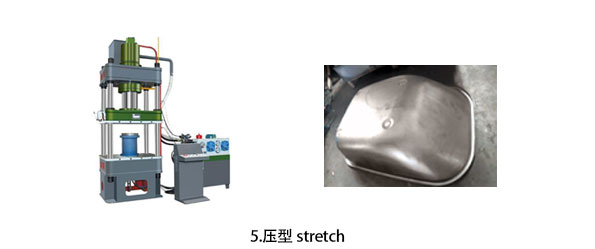

2. Stretching: When manufacturing a trolley, different pressures are required to achieve different effects. Here, a hydraulic press marked with Y32 or Y27 is recommended to be used with a mold.

First, a hydraulic press of 300 tons and above is needed to pull out the body part of the trolley with a mold.

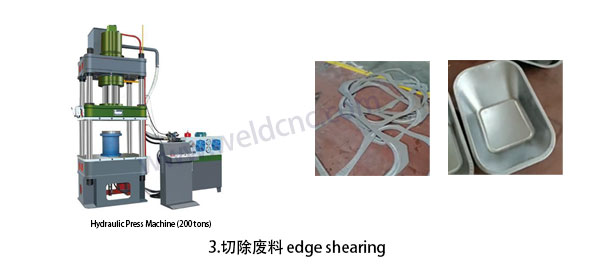

Then use a smaller tonnage hydraulic press with a die to stretch the edge and cut off the excess material.

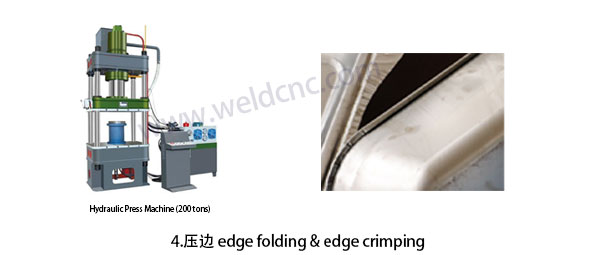

Use the same tonnage hydraulic press to replace the edge-sealing mold and press the edge to make the trolley body more safe and beautiful and not easy to deform.

The same tonnage hydraulic press, with the bottom mold, pulls out four connections with the steel pipe.

3. Punching: manufacturing various punching holes and logo information of the connecting part of the trolley

This part is mainly carried out according to the mold, and the corresponding mold can be customized according to your actual needs.

4. Cut the pipe: The size of the metal pipe purchased may not be suitable, and it needs to be cut to the required length.

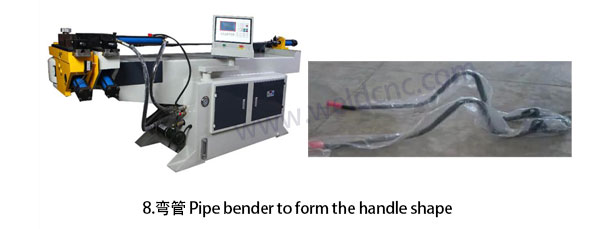

5. Bending tube: According to the drawing, bend the metal tube into the required shape, mainly the part of the frame.

6. Spraying: Brush the required metal surface with a layer of suitable paint to make the wheelbarrow more delicate and beautiful, which is welcomed by customers. If the budget allows, the spraying production line can be directly manufactured, the spraying efficiency is higher, the spraying effect is good, the labor is saved, and it is more convenient.

7. Connect the components to assemble the wheelbarrow.

The above is the basic equipment for manufacturing wheelbarrow production line. To sum up, a total of one shearing machine, one 300-ton hydraulic press, at least one 200-ton hydraulic press, four sets of matching hydraulic press molds (forming, cutting, trimming, pressing), one punch press, with 2 sets Dies (marking, punching), a pipe cutting machine, a pipe bending machine, a spraying line or a speed sprayer, and accessories such as wheel bearings.

The specific process is as follows

All the above products can be purchased as a set or individually. If you have any ordering needs, you can contact us directly, Whatsapp/Mob/Wechat: 0086 133 9411 0095, looking forward to your reply.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China