News

Troubleshooting: Aluminum Foil Lunch Box Feeder Not Working?

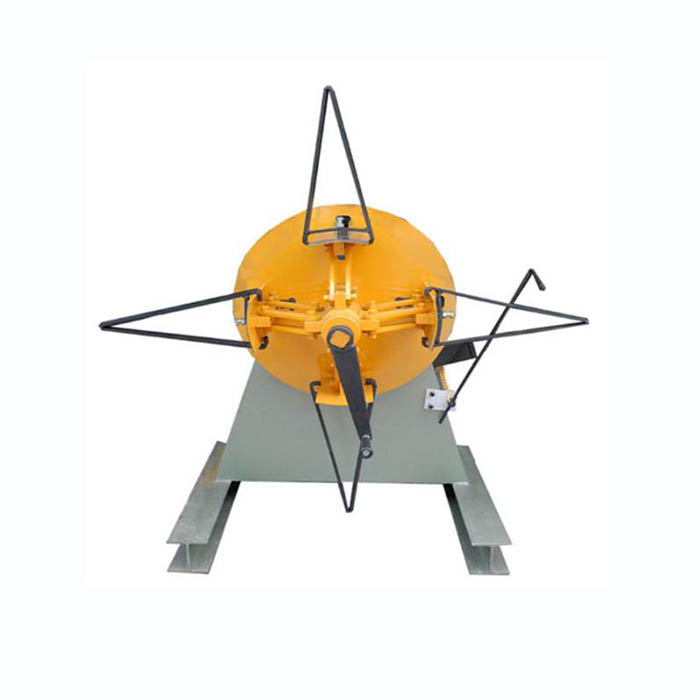

The feeder of the aluminum foil lunch box production line is the same as the ordinary feeder. If it is used for a long time and the maintenance is not paid attention to during the use, some small faults will occasionally occur. The most common is the feeding part of the feeder of the aluminum foil lunch box production line. The feeding is inaccurate, the feeding is biased, and the stamping parts are damaged due to insufficient feeding, which cannot meet the processing requirements.

Next, Jiuying analyzes the reasons for the inaccurate feeding of the feeder of the aluminum foil lunch box production line, and proposes solutions

1. The aluminum foil lunch box production line feeder not only has the function of feeding and leveling, but also has the function of automatic unwinding. While the multifunctional integrated structure makes it possible to avoid many small problems, some problems cannot be avoided. For example, there is garbage, steel filings or iron filings in the equipment, which will cause unstable meshing of the drum drive gears.

Solution: Make a daily maintenance list and clean the equipment regularly. Lubricate each transmission component regularly to remove foreign matter.

2. The stopper wheel is not adjusted correctly. You must know that the feeder of the aluminum foil lunch box production line feeder can roll in various thicknesses of materials. If the thickness of the last batch of processed material is different from the next batch and it is not adjusted in time, it will cause the roller and the material to be too tight or too loose and slip, resulting in inaccurate feeding.

Solution: Operators need to undergo rigorous technical training in machine operation before starting work. Or get technical support from the Foil Lunch Box Line Feeder Manufacturer to learn the correct operation for your production needs.

3. Material problems of the feeder of the aluminum foil lunch box production line, such as different material thickness, different burrs, different widths, etc. In this case, the feeding device is prone to inaccurate feeding.

Solution: replace new materials in time. Test several times.

4. The air pressure of the feeding roller of the feeder of the aluminum foil lunch box production line is insufficient, and the conveying of the material mainly depends on the rotation of the feeding roller to move forward. If the air pressure on the feed roller is insufficient, loosen it. Since the power source for relaxation is air pressure and is usually used with a punch press, vibration is inevitable. Due to vibrations, the associated set screws often loosen, affecting levelling and feeding accuracy.

Treatment method: You can check whether the lower roller is in a pressed state. If the pressure is not enough, it can be solved by increasing the roller set, increasing the spring or cylinder pressure.

5. There is another situation, it is not a device problem. For example, the position of the die of the punch press is unstable, the die is not positioned properly, and the movement during the feeding process indirectly leads to inaccurate feeding of the feeder of the aluminum foil lunch box production line.

Solution: Check the cause of the mold shift and deal with it in time.

The above is the solution to the problem of the feeder of the aluminum foil lunch box production line. Enterprises can check by themselves, or directly contact the website personnel to obtain professional after-sales service.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China