Shearing machine

QC11Y Series Hydraulic Guillotine metal plate Shearing Machine

QC11Y Series Hydraulic Guillotine metal plate Shearing Machine is a machine that uses one blade to reciprocate linear motion relative to the other blade to cut the plate. By means of a moving upper blade and a fixed lower blade, a reasonable blade gap is used to apply shearing force to metal plates of various thicknesses, so that the plates can be broken and separated according to the required size. The shearing machine is a kind of forging machinery, and its main function is the metal processing industry. The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment required.

Technical description of QC11Y Series Hydraulic Guillotine metal plate Shearing Machine:

The second generation hydraulic shearing machine. The frame and the tool holder adopt an integral welded structure, which eliminates vibration stress and has good accuracy retention.

It adopts advanced integrated hydraulic system with good reliability.

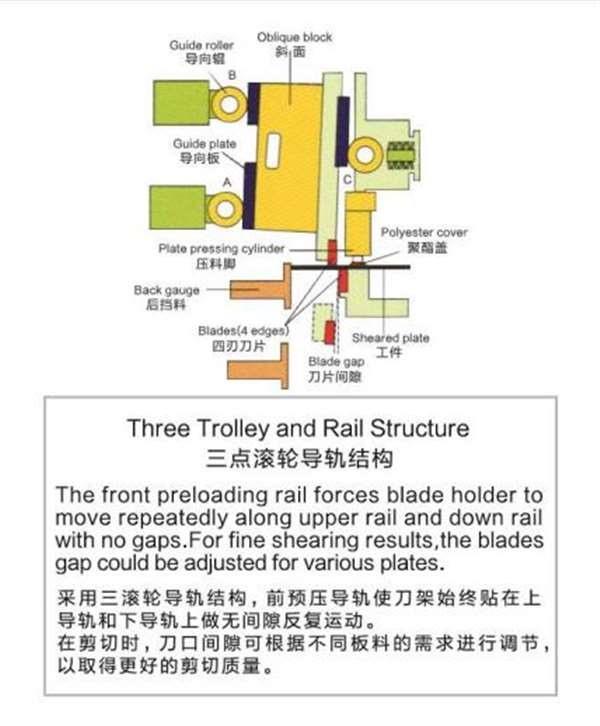

Three-point bearing rolling guide is used to eliminate bearing clearance and improve cutting quality.

The adjustment of the blade gap handwheel is fast, accurate and convenient.

Rectangular blade, all four cutting edges can be used, long service life.

The cutting angle can be adjusted to reduce the deformation of the metal plate.

The upper tool holder adopts an internal structure, which is convenient for punching and improves the accuracy of parts.

It has the function of segment cutting.

Electric tailgate, digital display.

QC11Y Series Hydraulic Guillotine metal plate Shearing Machine Working principle

After shearing, QC11Y Series Hydraulic Guillotine metal plate Shearing Machine should be able to ensure the straightness and parallelism of the shear surface of the sheared sheet, and minimize the distortion of the sheet to obtain high-quality workpieces. The upper blade of the shearing machine is fixed on the knife holder, and the lower blade is fixed on the workbench. A material holding ball is installed on the workbench to prevent the sheet from being scratched when sliding on it. The back gauge is used for positioning the plate, and the position is adjusted by the motor. The pressing cylinder is used to compress the sheet to prevent the sheet from moving during shearing. The guardrail is a safety device to prevent accidents at work. The return journey generally relies on nitrogen, which is fast and has little impact.

Features of QC11Y Series Hydraulic Guillotine metal plate Shearing Machine:

All-steel welded structure with sufficient strength and rigidity.

Hydraulic drive, nitrogen backflow.

The tool post is positioned by the rolling guide to eliminate the gap between the guides.

The cutting angle can be adjusted.

The cutting stroke can be adjusted.

Motor quick adjustment, manual fine adjustment, back gauge installation figures appear.

Quick adjustment of cutting edge clearance.

Counting and measuring installation.

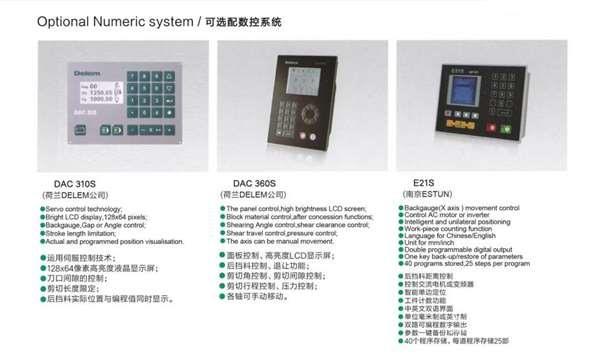

QC11Y/QC11A Hydraulic Guillotine Metal Sheet Shearing Machine series adopts Durham digital-to-analog converter-360 control system.

Technical parameters of QC11Y Series Hydraulic Guillotine metal plate Shearing Machine:

型 号 | 可剪板厚 | 可剪板宽 | 被剪板料强度 | 剪切角 | 后挡料距离 | 行程次数 | 喉口深度 | 电机功率 | 外形尺寸 |

Type | Cuting thickness | cutting length | Strength of sheared sheet | shear angle | Backgauge distance | Times of stroke | Throat Depth | motor power | Dimensions |

(mm) | (mm) | (N/mm2) | (。) | (mm) | (次/min) | (mm) | (KW) | (mm) | |

QC11Y/A-6×3200 | 6 | 3200 | 450 | 0.5-1.5 | 500 | 13-22 | 130 | 7.5 | 3900×1520×2100 |

QC11Y/A-6×4000 | 6 | 4000 | 450 | 0.5-1.5 | 500 | 8-15 | 130 | 7.5 | 4700×1770×2200 |

QC11Y/A-6×6000 | 6 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×1900×2550 |

QC11Y/A-8×2500 | 8 | 2500 | 450 | 0.5-2. | 500 | 14-24 | 130 | 7.5 | 3150×1580×2050 |

QC11Y/A-8×3200 | 8 | 3200 | 450 | 0.5-2. | 600 | 15-25 | 130 | 7.5 | 3740×2075×1920 |

QC11Y/A-8×4000 | 8 | 4000 | 450 | 0.5-2. | 500 | 8-14 | 130 | 11 | 4700×1840×2350 |

QC11Y/A-8×6000 | 8 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×2100×2750 |

QC11Y/A-10×2500 | 10 | 2500 | 450 | 0.5-2 | 500 | 12-24 | 130 | 11 | 3150×1670×2150 |

QC11Y/A-10×3200 | 10 | 3200 | 450 | 0.5-2 | 500 | 10-18 | 130 | 11 | 3900×1730×2250 |

QC11Y/A-10×4000 | 10 | 4000 | 450 | 0.5-2 | 750 | 7-12 | 130 | 18.5 | 4750×1900×2450 |

QC11Y/A-10×6000 | 10 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 18.5 | 6950×2200×2900 |

QC11Y/A-10×8000 | 10 | 8000 | 450 | 0.5-2 | 900 | 4-8 | 100 | 30 | 8950×2500×3150 |

QC11Y/A-12×2500 | 12 | 2500 | 450 | 0.5-2.5 | 750 | 10-18 | 130 | 18.5 | 3250×1800×2280 |

QC11Y/A-12×3200 | 12 | 3200 | 450 | 0.5-2.5 | 750 | 9-18 | 130 | 18.5 | 3950×1870×2350 |

QC11Y/A-12×4000 | 12 | 4000 | 450 | 0.5-2.5 | 750 | 7-12 | 130 | 18.5 | 4800×1970×2550 |

QC11Y/A-12×6000 | 12 | 6000 | 450 | 0.5-2.5 | 750 | 5-10 | 100 | 30 | 7000×2250×3000 |

QC11Y/A-12×8000 | 12 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×2500×3300 |

QC11Y/A-16×2500 | 16 | 2500 | 450 | 0.5-2.5 | 750 | 9-16 | 100 | 18.5 | 3290×1890×2400 |

QC11Y/A-16×3200 | 16 | 3200 | 450 | 0.5-2.5 | 750 | 8-13 | 100 | 18.5 | 3970×1920×2520 |

QC11Y/A-16×4000 | 16 | 4000 | 450 | 0.5-2.5 | 750 | 9-12 | 100 | 30 | 9000×2500×3300 |

QC11Y/A-16×6000 | 16 | 6000 | 450 | 0.5-2.5 | 900 | 5-10 | 100 | 37 | 7100×2460×2920 |

QC11Y/A-16×8000 | 16 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×265×3400 |

QC11Y/A-16×9000 | 16 | 9000 | 450 | 0.5-2.5 | 900 | 3-8 | 100 | 45 | 10000×3260×3950 |

QC11Y/A-20×2500 | 20 | 2500 | 450 | 0.5-2.5 | 750 | 8-16 | 130 | 30 | 3350×2050×2500 |

QC11Y/A-20×3200 | 20 | 3200 | 450 | 0.5-2.5 | 750 | 5-14 | 130 | 30 | 4100×2080×2550 |

QC11Y/A-20×4000 | 20 | 4000 | 450 | 0.5-3 | 750 | 5-12 | 100 | 30 | 4900×2200×2800 |

QC11Y/A-20×6000 | 20 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 37 | 7100×2600×3250 |

QC11Y/A-20×9000 | 20 | 9000 | 450 | 0.5-2.5 | 900 | 3-7 | 100 | 55 | 10050×3350×4000 |

QC11Y/A-25×2500 | 25 | 2500 | 450 | 0.5-3 | 900 | 6-14 | 100 | 37 | 3500×2150×2600 |

QC11Y/A-25×3200 | 25 | 3200 | 450 | 0.5-3 | 900 | 5-11 | 100 | 37 | 4100×2150×2650 |

QC11Y/A-25×4000 | 25 | 4000 | 450 | 0.5-3 | 900 | 5-10 | 100 | 37 | 4900×2280×3350 |

QC11Y/A-25×6000 | 25 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 45 | 7100×2680×3350 |

QC11Y/A-30×2500 | 30 | 2500 | 450 | 0.5-3.5 | 900 | 5-11 | 100 | 45 | 3700×2570×3100 |

QC11Y/A-30×3200 | 30 | 3200 | 450 | 0.5-3.5 | 900 | 5-9 | 100 | 45 | 4400×2800×3250 |

QC11Y/A-30×4000 | 30 | 4000 | 450 | 0.5-3.5 | 900 | 4-9 | 100 | 55 | 5200×3000×3400 |

QC11Y/A-30×6000 | 30 | 6000 | 450 | 0.5-3.5 | 900 | 4-8 | 100 | 55 | 7100×3000×3600 |

QC11Y/A-40×2500 | 40 | 2500 | 450 | 0.5-4 | 900 | 4-11 | 100 | 55 | 3950×3020×3300 |

* Note: Due to technical and technological improvements, the parameters such as product color, structure and weight are subject to change without prior notice. The company reserves the right of final interpretation of this information.

FAQ

Q1:How to get the most suitable model and price for QC11Y Series Hydraulic Guillotine metal plate Shearing Machine?

A:You need tell us this info: plate material ,thickness and length, then we choose suitable model

Q2:Are you a factory or a trading company?

A:Jiuying heavymachine Co., Ltd is a professional manufacturer of press brake, shearing machine , rollingmachine,cutting machine and other sheet metal equipments.We have more than 14 years of manufacturing experience, and our products were exported to more than 34 countries and regions.

Q3:What if we don't know how to operate your machine?

A:Detailed installation and operation instructions are attached to the QC11Y Series Hydraulic Guillotine metal plate Shearing Machine, you could operate the machine according to it.Besides, we will provide video technical support and online support.Or we could arrange our engineer to your country to teach you how to use it and maintain it.Also, you could send your technician to our factory, we will give him related training.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China