Rolling machine

W12 series four-roller metal plate rolling machines

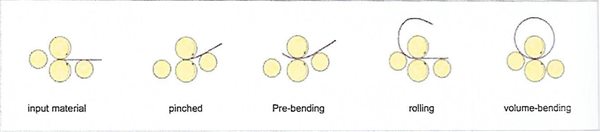

W12 series four-roller metal plate rolling machines has the pre-bending function of the plate end, which can load the metal plate at one time, and can complete the plate end pre-bending and the roll forming of the workpiece without turning. The upper working roller of this machine is the main driving roller. The lifting of the lower roller and the rollers on both sides adopts hydraulic transmission. The lifting displacement is controlled by computer, automatic leveling, screen display, and the tilting and resetting of the turning bearing body adopts hydraulic transmission. The tail of the upper roller Equipped with a balance mechanism, it is convenient to unload the rolled workpiece and cylinder. Equipped with a mobile independent operating table, which can be moved and operated at any time. The machine is equipped with a safety interlock device. The machine has high technical level, complete functions, high precision and convenient operation. It is the most ideal model for rolling round, arc and conical workpieces in industries such as energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structures.

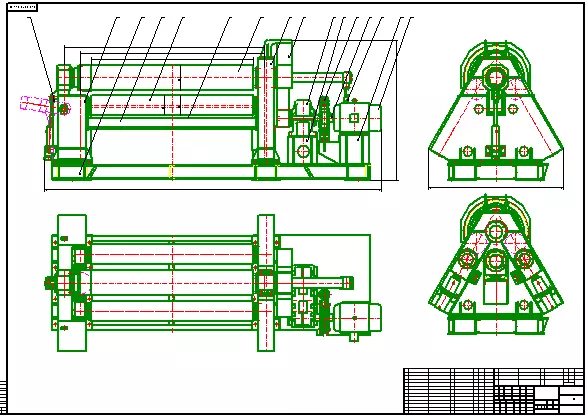

W12 series four-roller metal plate rolling machines Detail map

W12 series four-roller metal plate rolling machines working principle

W12 series four-roller metal plate rolling machines product description

1. This model is a digital display control system, the large-screen display is intuitive and clear, the value is accurate and reliable, the operation is simple and easy to use. The system is equipped with various interlocking interconnection protection measures to effectively prevent misoperation.

2. The operating system is equipped with an EPS electronic automatic leveling system, which can automatically adjust the parallelism of the motion axis to ensure product quality.

3. The equipment's material alignment, pre-bending, and rounding are completed in one rolling process. The remaining straight edge of the pre-bending is less than or equal to 1.5 times the plate thickness, and the rounding accuracy is high, which can meet the requirements of automatic welding.

4. This model adopts inverted side roller cylinder technology, which can effectively reduce the height of the fuselage while improving sliding stability and reducing equipment failures, meeting the ground installation requirements to a greater extent, and reducing user equipment foundation pits and other infrastructure construction costs.

5. In strict accordance with the process requirements, annealing and shot blasting the welding parts such as the frame to remove the internal pressure and improve the strength and stability of the machine body.

6. The equipment can be optionally equipped with internal lifting racks and external brackets, which can effectively control the weight deformation of the workpiece during the rolling process, assist the rolling, reduce labor, and improve product quality and work efficiency.

7. The equipment can be equipped with four-roller plate rolling machine's upper roller taper device technology, which can meet the requirements of users for rolling tapered workpieces, and has the advantages of convenient operation, low use cost, and good rolling quality.

W12 series four-roller metal plate rolling machines Product number

Model | Max bergulir ketebalan * panjang最大板厚*长 | Diameter Roll Utama直径 | Diameter Sisi Roll下辊直径 | Bergulir Kecepatan滚动速度 | Motor utama主电机 |

MM | MM | MM | M/min | KW | |

W12-4x1500 | 4x1500 | 140 | 120 | 4 | 2.2 |

W12-4x2000 | 4x2000 | 160 | 140 | 4 | 2.2 |

W12-4x2500 | 4x2500 | 190 | 150 | 4 | 3 |

W12-4x3000 | 4x3000 | 210 | 170 | 4 | 7.5 |

W12-4x4000 | 4x4000 | 270 | 210 | 4 | 5.5 |

W12-6x2000 | 6x2000 | 190 | 150 | 4 | 5.5 |

W12-6x2500 | 6X2500 | 210 | 170 | 4 | 7.5 |

W12-8x1500 | 8x1500 | 200 | 170 | 4 | 5.5 |

W12-8x2000 | 8x2000 | 210 | 180 | 4 | 7.5 |

W12-10X2000 | 10x2000 | 230 | 180 | 4 | 7.5 |

W12-10X2500 | 10x2500 | 270 | 210 | 4 | 11 |

W12-12x2000 | 12x2000 | 245 | 200 | 4 | 11 |

W12-12x2500 | 12x2500 | 265 | 220 | 4 | 11 |

W12-16x2000 | 16x2000 | 250 | 210 | 4 | 15 |

W12-16x2500 | 16x2500 | 300 | 240 | 4 | 15 |

W12-20x2000 | 20x2000 | 300 | 250 | 4 | 18.5 |

W12-20x2500 | 20x2500 | 350 | 280 | 4 | 18.5 |

W12-25X2000 | 25x2000 | 360 | 250 | 4 | 15 |

W12-25X2500 | 25x2500 | 390 | 300 | 4 | 18.5 |

W12-30x2500 | 30x2500 | 410 | 340 | 4 | 22 |

W12-30x3000 | 30x3000 | 450 | 380 | 4 | 30 |

W12-35x2000 | 35x2000 | 430 | 330 | 4 | 30 |

W12-35x2500 | 35x2500 | 460 | 360 | 4 | 30 |

W12-40x2500 | 40x2500 | 500 | 420 | 4 | 37 |

W12-40x3000 | 40x3000 | 540 | 440 | 4 | 45 |

W12-45x2500 | 45x2500 | 460 | 420 | 4 | 30 |

W12-45x3000 | 45x3000 | 510 | 460 | 4 | 37 |

W12-50x2500 | 50x2500 | 560 | 450 | 4 | 45 |

W12-50x3000 | 50x3000 | 600 | 480 | 4 | 55 |

W12-60x2500 | 60x2500 | 610 | 500 | 4 | 55 |

W12-60x3000 | 60x3000 | 650 | 520 | 4 | 75 |

W12-65x3000 | 65x3000 | 650 | 550 | 4 | 55 |

W12-85x3000 | 85x3000 | 760 | 680 | 4 | 75 |

The parameters are for reference only, please add the QR code on the left for specific information and consult the staff.

FAQ

Q:Are you a manufacturer or a trading company?

A:We are a manufacturer; We specialize in metal sheet metal steel processing equipment.

Q.How about the shipping fees for W12 series four-roller metal plate rolling machines?

A:The shipping cost depends on the way you choose to get the goods.Express is normally the most quickest but also most expensive way.By seafreight is the best solution for big amounts.Exactly freight rates we can only give you if we know the details of amount, weight and way.Please contact us for further information.

Q:What kinds of payment methods do you accept?

A:You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

Q:How can we provide you efficient services (metal processing solution)?

A:There are Three Steps as following:

1.Gather your requirements based on your real working situation.

2.Analyze your information and provide our feedback.

3.Offer options based on your specific needs.For instance, reg.standard products, we can offer professional recommendations ;reg.non-standard products, we can offer professional designing.

Q:How long is the warranty period of W12 series four-roller metal plate rolling machines?

A:We warranty our materials and workmanship.Our commitment is to your satisfaction with our products.We commitment to client machines are one-year warranty.In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

Q:If the W12 series four-roller metal plate rolling machines is out-of-warranty, how to charge the cost of accessories?

A:1.Within the warranty period,we will offer spare parts for damaged parts that have not been damaged due to incorrect operation.The warranty period is 12 months from the date of the B/L.

2.Outside of the warranty period,replacement parts for electrical components are available in your local area as they are all sourced from international known brands.Customers can also contact us and we will offer spare parts at cost.We will also assist you in purchasing options in your local area in order to solve problem as quickly as possible.

3.If you need us to perform on site service,we will send a technician,and you will be in charge of the costs of transportation,accommodations and salaries.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China