Rolling machine

W11S Series 3-Roller Universal Plate Bending Machine

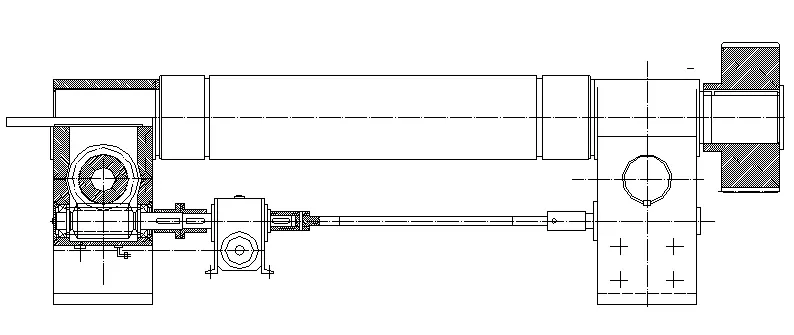

The main structure of the W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine includes an upper roller device and a horizontal moving device, a lower roller device, a main device roller transmission device, an end device, a left and right range and a base.

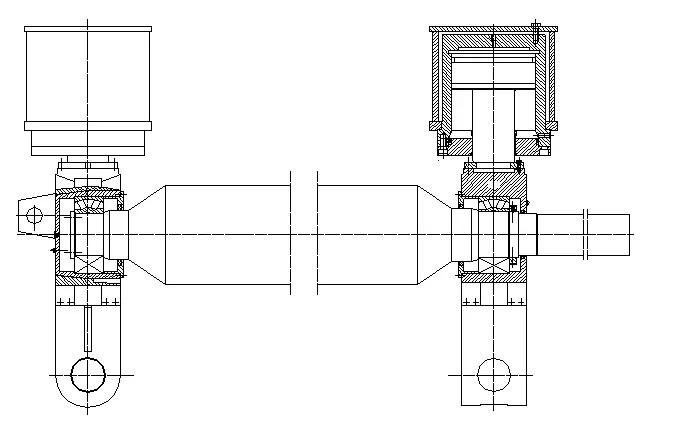

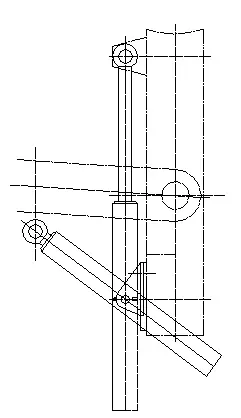

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Upper roller device

The upper roller device consists of a master cylinder, roller bearings, rollers, double-row self-aligning bearings and other components. Two main cylinders provide the required roll paper pressure, and the working pressure of the main cylinder is 19.5 MPa. Two rows of low-speed self-aligning bearings, heavy-duty spherical roller bearings.

The roller is made of 42CrMo steel, after rough machining, cooling HB260~300, according to JB/ZG4289-86 standard steel, rigidity according to (1/700-1/1000) L (L-refers to the distance between the two sides of the center line frame). The surface is coated to ensure that the workpiece is free from scratches.

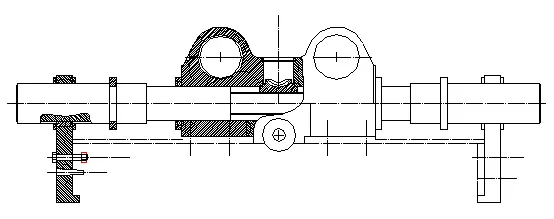

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Lower roller and horizontal movement device

The low roller is composed of low roller, low roller bearing, low roller, input gear, low roller, bearing and other components.

The same material as the low roll 42CrMo. According to JB/ZG4289-86 standard steel, HB240~280 is cooled and rough machined. The stiffness is referred to according to (1/700-1/1000) LL-between the center lines on both sides of the frame The distance between. The surface is coated to ensure that the workpiece is free from scratches.

SF-2 self-lubricating composite material is selected for low roller bearings.

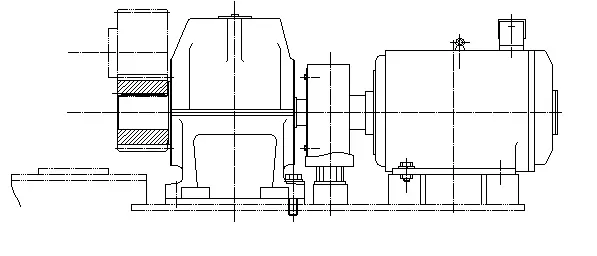

The level of the mobile equipment is achieved by the horizontal movement of the motor through the worm and worm (the worm uses ZQAl9-4), the worm and nut mechanism, which is driven by the movement of the horizontal roller assembly to achieve asymmetric rolling of the sheet.

The lower main driving roller is supported by the main transmission output, and the next gear roller input gear is turned on to drive the low torque roller.

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Roller device

The supporting roller device is composed of a wedge mechanism and a supporting roller mechanism.

The roller is made of 45 steel, and the hardness after quenching and tempering is HB280~320. The surface is coated, which is lower than the surface hardness under the roller surface.

The total number of the two idler sets is four, which correspond to the roll paper of the load size adjusted up and down.

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Equipment tips

The tipping device consists of a cylindrical rammer tipping and other components.

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Fix the tip side of the chassis frame

Fixed inverted side welded steel frame chassis, eliminating the fire after welding.

The fixed tip side frame can accommodate two master cylinders.

The chassis adopts a frame structure, high-torque section modulus, and fewer bolt installation and debugging.

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine

High-precision end pre-bending: When the end pre-bending, the length of the straight side can be set freely, the upper roll is pressed down, and the high-precision end pre-bending is performed under a certain pressure.

Excellent product accuracy: Due to continuous bending and high-precision end pre-bending, products with excellent accuracy are obtained. In addition, the upper roller is in the shape of a drum, and the supporting rollers are coordinated and adjusted. It can be rolled in a wide range from thin plates to thick plates. The ideal product.

Corresponding control methods for different purposes: According to the purpose, there are the following control methods: TNC (Upper NC), multi-variety and small-scale production. T&BNC (upper and lower NC), for mass production of small varieties. CNC (CNC), for mass production of multiple varieties.

CNC control high production efficiency: one person works, simple operation, greatly improved efficiency.

Abundant bending shapes: There are different shapes such as rolled O-shaped, U-shaped, multi-segment R, and the way: O-shaped bending: rear bending. U-shaped bending: forward bending method. Special bending: combined method.

Features of W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine:

This is a high-precision bendable free board width setting.

The final plate to be used for the upper roll bending.

The roller allows continuous bending of boards of any thickness.

The table roller press can work safely by pressing down two rollers and the top one

Perform horizontal and vertical movement, as long as the top of the cylinder moves, the printing plate will not move.

W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine Product parameter

odel | Tekanan | Max.rolling | Max.rolling | Atas roller Diameter | Bawah roller Diameter | Rol Jarak | Motor | |||

Ton | Mm | Kw | ||||||||

Bending | Max membungkuk | Mm | Mm | Mm | Mm | Mengemudi | Hidrolik | Bergerak | ||

Mm | Mm | |||||||||

W11S-6x1500 | 25 | 4.8 | 6 | 1500 | 175 | 125 | 160 | 3 | 2.2 | 0.75 |

W11S-6x2000 | 25 | 4.8 | 6 | 2000 | 195 | 125 | 160 | 3 | 2.2 | 0.75 |

W11S-6x2500 | 25 | 4.8 | 6 | 2500 | 205 | 135 | 180 | 3 | 2.2 | 0.75 |

W11S-6x3000 | 37 | 4.8 | 6 | 3000 | 215 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-8x1500 | 25 | 6.4 | 8 | 1500 | 175 | 125 | 160 | 3 | 2.2 | 0.75 |

W11S-8x2000 | 25 | 6.4 | 8 | 2000 | 195 | 125 | 160 | 3 | 2.2 | 0.75 |

W11S-8x2500 | 37 | 6.4 | 8 | 2500 | 205 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-8x3000 | 45 | 6.4 | 8 | 3000 | 215 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-10x1500 | 37 | 8 | 10 | 1500 | 205 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-10x2000 | 45 | 8 | 10 | 2000 | 215 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-10x2500 | 45 | 8 | 10 | 2500 | 235 | 135 | 180 | 4 | 2.2 | 0.75 |

W11S-10x3000 | 65 | 8 | 10 | 3000 | 245 | 135 | 180 | 5.5 | 4 | 0.75 |

W11S-10x4000 | 75 | 8 | 10 | 4000 | 255 | 150 | 245 | 7.5 | 4 | 1.1 |

W11S-12x2000 | 65 | 9.6 | 12 | 2000 | 250 | 145 | 200 | 5.5 | 4 | 0.75 |

W11S-12x2500 | 65 | 9.6 | 12 | 2500 | 255 | 150 | 245 | 5.5 | 4 | 0.75 |

W11S-12x3000 | 75 | 9.6 | 12 | 3000 | 270 | 150 | 245 | 7.5 | 4 | 1.1 |

W11S-12x6000 | 100 | 9.6 | 12 | 6000 | 290 | 150 | 245 | 15 | 5.5 | 1.5 |

W11S-16x2000 | 75 | 12.8 | 16 | 2000 | 255 | 150 | 245 | 7.5 | 4 | 1.1 |

W11S-16x2500 | 100 | 12.8 | 16 | 2500 | 270 | 150 | 245 | 15 | 5.5 | 1.5 |

W11S-16x3200 | 100 | 12.8 | 16 | 3200 | 290 | 150 | 245 | 15 | 5.5 | 1.5 |

W11S-16x6000 | 190 | 12.8 | 16 | 6000 | 300 | 165 | 270 | 22 | 7.5 | 4 |

W11S-20x2000 | 100 | 16 | 20 | 2000 | 325 | 165 | 270 | 15 | 5.5 | 1.5 |

W11S-20x2500 | 130 | 16 | 20 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 1.5 |

W11S-20x3000 | 160 | 16 | 20 | 3000 | 350 | 180 | 300 | 18.5 | 7.5 | 2.2 |

W11S-20x4000 | 190 | 16 | 20 | 4000 | 360 | 200 | 330 | 22 | 7.5 | 4 |

W11S-20x6000 | 380 | 16 | 20 | 6000 | 375 | 200 | 330 | 45 | 22 | 5.5 |

W11S-25x2000 | 160 | 20 | 25 | 2000 | 330 | 180 | 300 | 18.5 | 7.5 | 2.2 |

W11S-25x2500 | 190 | 20 | 25 | 2500 | 350 | 180 | 300 | 22 | 7.5 | 4 |

The parameters are for reference only, please add the QR code on the left for specific information and consult the staff.

FAQ

Q:Can you give me a better price for W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine?

A:The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

Q:Does your company accept customized offer, we have special need.

A:JiuYing is a company that focuses on research and manufacture of modular cnc machines.We have a very rich experience and strong machine tool research and development capability.We are very willing to offer you customized highly-efficient equipment as long as you have certain amount of needs.

Q:Do you have price list for optional configuration for W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine?

A:We have various configurations and so many different specifications, so we can’t offer you price list.Please contact our sales engineer if you’re interested in certain specific configuration.

Q:What I would do for the machine failure for W11S Series 3-roller Top Roller Universal Rolling Machine/Plate Bending Machine?

A:If the machine malfunction and users are unable to resolve, please email us for consultation.Our service department will respond within 24 hours.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China