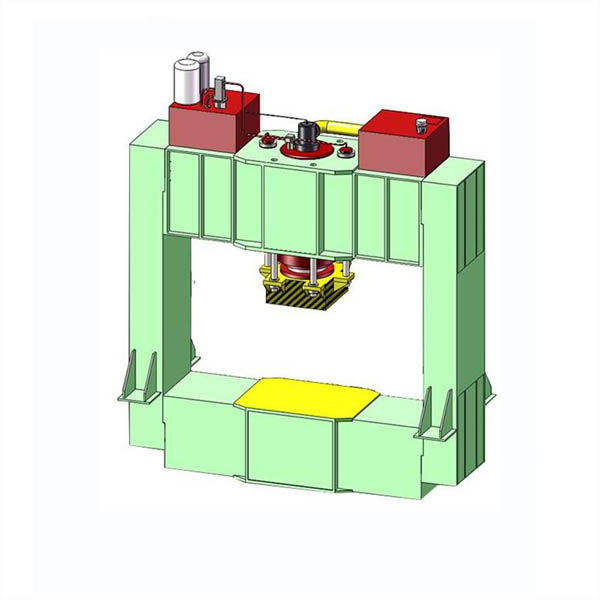

Head Forming machine

Ball Shell Head Hydraulic Drum Press Machine

Ball Shell Head Hydraulic Drum Press Machine

Equipment main technical performance and configuration

1. The equipment has stroke digital display and press stroke NUMERICAL control;

Pressure digital display and NUMERICAL control;

Stroke and pressure can be controlled separately.

This ensures smooth and even curvature of each batch of pellets during pressing due to the same pressing stroke setting.

2. The main pillar seal adopts the American chardonnay technology products of Guangzhou Research Institute.

3. The main cylinder and the main plunger are made of high-quality carbon steel forgings.Forgings with master cylinder up to grade 3 inspection standard, main plunger treated with tempering, chrome plated.(Adjustment - grinding - plating - polishing)

4. Qidong high-pressure pump is adopted in the oil pump.

5. Siemens is adopted in PLC.

6. The insertion valve adopts Shanghai navigational instruments.

7. Solenoid directional valve adopts German Rexroth technology of Beijing Huade products.

8. Other electrical components are made by Schneider.

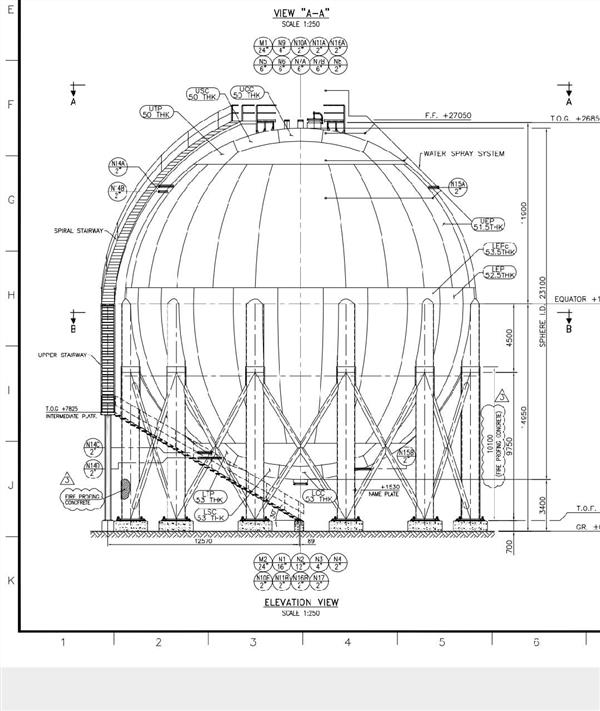

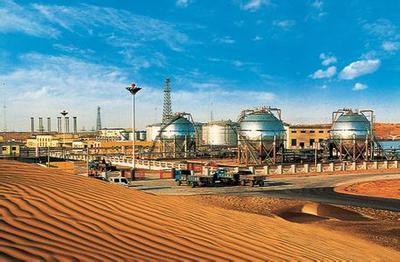

National standard head is an important component of pressure vessel equipment from petrochemical industry and atomic energy industry to food manufacturing industry.

Thick-walled head is also called elliptical head and elliptical head is a head composed of two parts: a rotating elliptical sphere and a cylindrical straight section.

The elliptic head with the ratio of long and short axes of the rotating elliptic spherical bus is 2.0, which is customarily referred to as the standard elliptic head.

Spherical head, also known as spherical head, is the head formed by the crown part of the spherical shell, there are hemispherical head and no fringing spherical head.

Most pressure vessels use hemispheric head as end head, which has the advantages of small surface area under the same volume and thin thickness required under the same pressure condition, which is reasonable from the perspective of material saving and strength.

The unflanged spherical head is fillet welded to the simplified one. It is usually used as the middle head of the two pressure Chambers in the container, or as the end head.

Ball Shell Head Hydraulic Drum Press Machine Product processing

FAQ

Q:What's the price and specification of Ball Shell Head Hydraulic Drum Press Machine?

A:JIUYING always provide high quality machine, as we know,oversea market is more important and difficult than domestic market because of communication time costing after sales.So always,our machines has enough quality standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think advance for the clients.Please let me know the utensil diameter and height, the pictures and drawing will be better, so that we can check and recommend suitable machine for you.

Q:How about your machine quality?We are worry about the quality.

A:JIUYING is a mature brand in China.through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 32 countries where there are metal plate industry.

Q:How long is the warranty period of the Ball Shell Head Hydraulic Drum Press Machine?

A:Our product quality guarantee period is 12 months from B/L date.During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us.If the malfunctions are caused by customers' incorrect operations, we willprovide customers spare parts at cost price.We also can offer flexible extended warranties according to the actual situation.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China