News

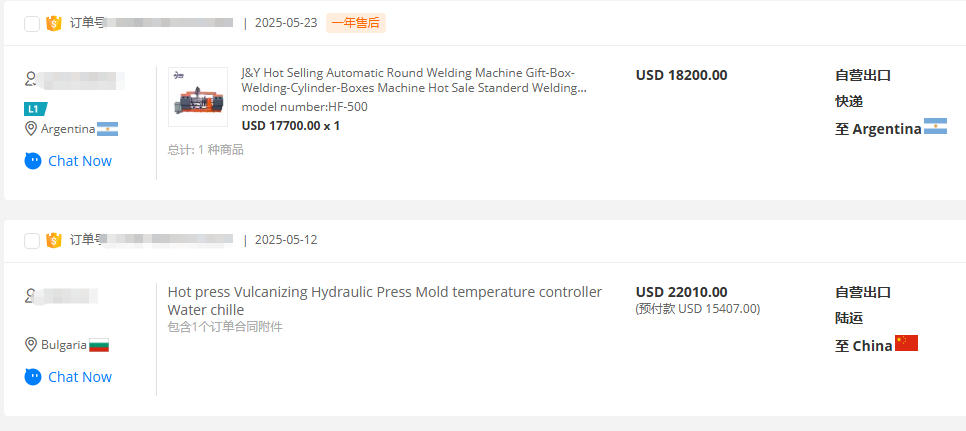

New Order from Argentina: Automatic Girth Welding Machines

We are excited to announce a new order from Argentina for our cutting-edge Automatic Girth Welding Machines. This marks another significant milestone in our global reach, as we continue to provide top-tier welding solutions to industries worldwide.

Automatic Girth Welding Technology

Automatic girth welding machines combine arc welding with automated control for precise and efficient operation. The high-energy arc melts the interface between the electrode and workpiece to form a molten pool. A programmable controller adjusts parameters like current, voltage, and speed to ensure uniformity. By compressing the arc plasma, energy density is improved, allowing for deeper penetration (6mm) and reducing the heat-affected zone by 40%, minimizing deformation.

The system’s double-end clamping-rotation mechanism ensures stability, while the welding gun control system allows for 0.1mm precision adjustments. High-end models even feature a swing module for V-groove welding. The gas protection unit and flux recycling system ensure consistent quality while minimizing waste.

Key Advantages and Industry Impact

Automatic girth welding machines significantly reduce defects, with an RT detection pass rate above 99.5%. Their continuous operation boosts welding efficiency, doubling per capita production. Labor costs are reduced by up to 40%, thanks to decreased reliance on skilled welders.

The technology’s impact spans various industries: valve manufacturing, large-scale construction, and nuclear power projects. For instance, in valve production, welding time is reduced from 10 minutes to 1.5 minutes, increasing output. In large-scale projects like blast furnaces, multi-layer welding is completed 15 times faster than manual methods. In nuclear power, mobile robots automate up to 90% of welding, reducing labor costs by 60%.

Future Trends in Girth Welding

Looking ahead, the future of automatic girth welding lies in multi-machine collaboration and low-carbon processes. The industrial internet will enable unmanned scheduling, while low-temperature steel welding will benefit from QSPT primer technology, reducing heat input by 30%. Mobile robots are expanding into new sectors like wind turbine towers and LNG storage tanks, reshaping heavy equipment manufacturing through greater precision, efficiency, and sustainability.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China