News

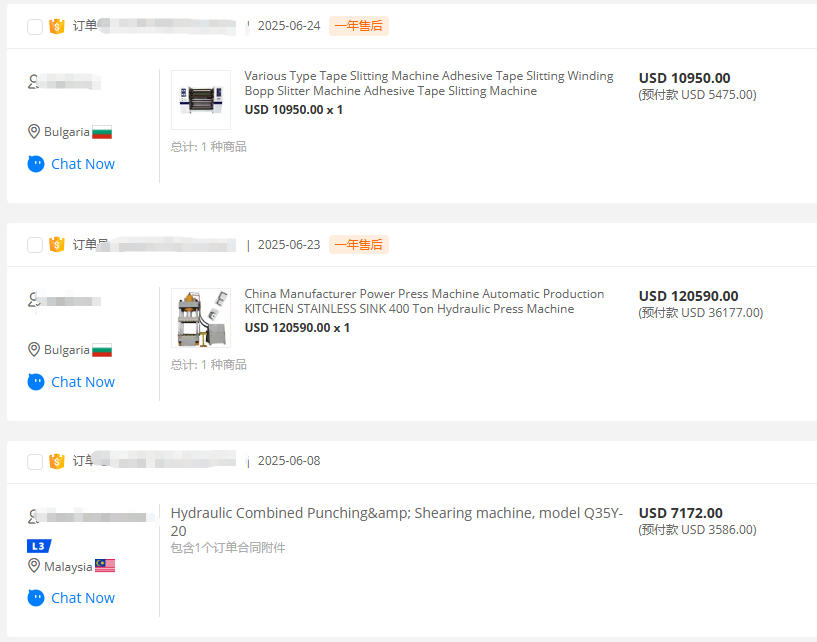

New Order: Hydraulic Press for Metal Sink Production

We are excited to announce a new order for our stainless steel water tank stretching hydraulic press, which will be used in the production of metal sinks. This order highlights the versatility of our equipment, proving that it’s not only ideal for stainless steel water tank production but also perfectly suited for other metal forming applications. Our hydraulic press continues to provide reliable, high-quality performance across various industries, and we’re proud to support our clients in producing top-tier metal products.

Stainless Steel Water Tank Stretching Hydraulic Press

Our stainless steel water tank stretching hydraulic press is designed for precision and reliability in the production of water tanks and other metal forming applications. It adopts either a three-beam four-column structure (economical and practical) or a frame design (high anti-eccentric load capacity). The integrated hydraulic system ensures low leakage control, contributing to efficient and long-lasting performance.

The press coordinates the main cylinder, lower top cylinder, and side cylinders to complete multiple actions, such as stretching forming, edge pressing positioning, material removal, and demoulding. The movable crossbeam features a two-stage speed control: fast drop (100-250mm/s) for efficiency and slow mold support (5-15mm/s) for precision.

Custom Tonnage and Control Features

Tonnage selection must match the specifications of the water tank. The 200-250 ton models (working table dimensions from 660×660mm to 930×900mm, stroke 600-610mm) are ideal for single-slot and small double-slot tanks. For large multi-slot or thick plate tanks (≥1.2mm), models above 400 tons (working table ≥1400×1400mm, stroke ≥800mm) are recommended for deep drawing, with a top force of 63-100 tons.

The core process uses independent blanking force adjustment (50%-70% of the main cylinder pressure) to prevent wrinkling and cracking. This, combined with integrated "stretching-trimming-punching" processing, reduces positioning errors and enhances production accuracy.

The machine features a PLC touch screen control system with safety protections, such as light curtain monitoring, cylinder interlocking, and stroke limits. For increased productivity, hydraulic pads and quick mold change systems are available. Maintenance requires annual replacement and filtration of ISO AW46 anti-wear hydraulic oil, daily lubrication of the columns, and semi-annual calibration of pressure gauges to maintain optimal performance.

Tonnage Selection and Customization

For small single-slot machines, we recommend a 200-250 ton four-column hydraulic press. For large multi-slot or thick plate production, choose a frame machine with over 400 tons of tonnage. Customizations are available based on water tank size, material thickness, and production capacity, with workbenches accommodating up to 2500×1800mm and a maximum stroke of 900mm.

Welcome to Order

Welcome to order your stainless steel water tank stretching hydraulic press from us! Our machines offer reliable performance, high precision, and customizable solutions for producing water tanks, metal sinks, and other products. Contact us today to learn how we can support your business.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China