News

Garden Cart Production Line Guide

Introduction to Garden Cart Production

In today's rapidly evolving industrial landscape, the demand for garden carts, also known as wheelbarrows, continues to rise. As more people engage in gardening and landscaping activities, the need for efficient and durable garden carts becomes paramount. Establishing a production line dedicated to manufacturing garden carts can be a lucrative venture for factories seeking to diversify their product offerings. In this article, we will delve into the intricacies of setting up a garden cart production line, detailing the production process, required machinery, costs involved, and projected annual/monthly production capacity.

Production Process

- Design and Prototyping: The production process begins with designing the garden cart. This involves conceptualizing ergonomic designs that prioritize functionality, durability, and ease of use. Prototyping is crucial to refine the design and ensure it meets market requirements.

- Material Procurement: Once the design is finalized, the next step is procuring raw materials such as steel, aluminum, or plastic, depending on the intended design and specifications of the garden cart.

- Cutting and Shaping: The raw materials are then cut and shaped according to the design using specialized machinery such as laser cutters, hydraulic shears, and stamping presses. Precision is essential to ensure uniformity and quality in the final product.

- Welding and Assembly: Components of the garden cart are welded together to form the frame and body. Advanced welding techniques like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding may be employed to ensure strong and durable joints. Subsequently, other parts such as handles, wheels, and support structures are assembled onto the frame.

- Surface Treatment: Surface treatment processes such as powder coating or painting are applied to enhance the aesthetic appeal of the garden cart and provide protection against corrosion and wear.

- Quality Control: Stringent quality control measures are implemented throughout the production process to detect and rectify any defects or discrepancies. This ensures that the final product meets industry standards and customer expectations.

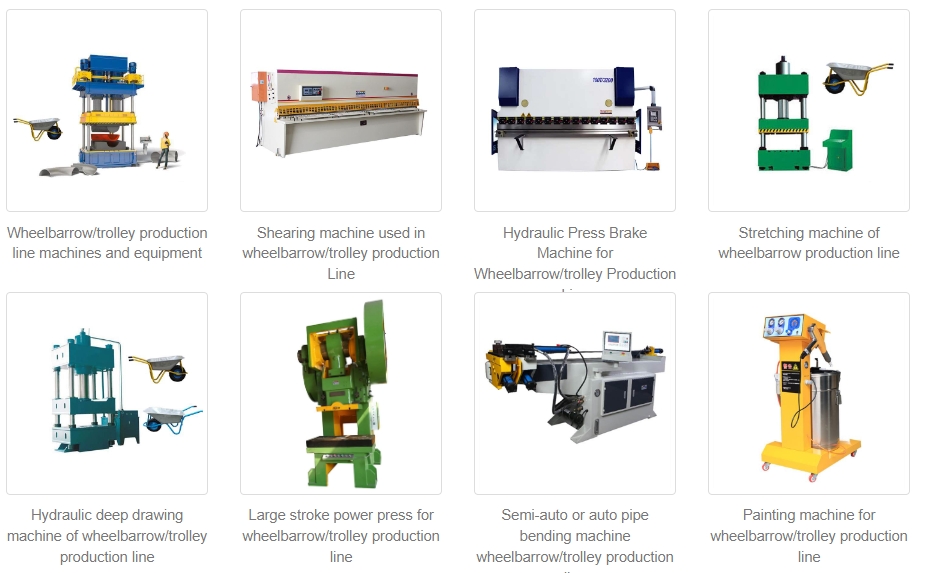

Machinery Required

Setting up a garden cart production line requires the following machinery:

Laser Cutters

Hydraulic Shears

Stamping Presses

Welding Machines (MIG/TIG)

Assembly Line Equipment

Powder Coating/Painting Equipment

Quality Control Tools (inspection gauges, measuring instruments)

Cost Analysis

The cost of establishing a garden cart production line varies depending on factors such as the scale of operations, the choice of machinery, labor costs, and facility expenses. A comprehensive cost analysis should include:

Machinery and Equipment Costs

Raw Material Expenses

Labor Costs

Facility Rent/Lease

Utility Expenses

Regulatory Compliance Costs

Miscellaneous Expenses (transportation, packaging, etc.)

Annual/Monthly Production Capacity

The production capacity of a garden cart production line is influenced by factors such as equipment efficiency, workforce productivity, and market demand. A well-optimized production line can achieve the following production capacities:

Annual Production: 50,000 - 100,000 units

Monthly Production: 4,000 - 8,000 units

Conclusion

Establishing a garden cart production line requires careful planning, investment, and attention to detail. By following a systematic production process, investing in the right machinery, and maintaining high-quality standards, factories can meet the growing demand for garden carts while ensuring profitability and customer satisfaction.

For inquiries regarding setting up a garden cart production line or procuring machinery, please contact Jiuying (JY) Machinery Co., Ltd. through the following link: Contact Us. Our experienced team is ready to assist you in realizing your production goals.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China