Bending machine

WC67Y series hydraulic metal plate bending machine/press brake

WC67Y series hydraulic metal plate bending machine/press brake, the whole machine adopts steel plate welding structure, vibration aging eliminates internal stress, high machine strength and good rigidity; hydraulic double cylinder upper transmission, mechanical block, torsion axis synchronization, stable and reliable operation, national standard accuracy ; Backgauge interval and slider stroke adopt electric adjustment and manual fine-tuning, and equipped with digital display installation, convenient and quick to use;

The upper die is equipped with a deflection compensation device; WC67Y series hydraulic servo CNC sheet metal bending machine/press brake model can be equipped with special digital display systems E21, E200, etc., with digital display of back gauge and upper slide position, X/Y axis soft limit, and one-way positioning gap prompt function. Both the gauge and the upper slide are equipped with encoders, and the digital display system makes the position value of the back gauge and the upper slide accurately displayed, thereby further improving the working accuracy of the machine.

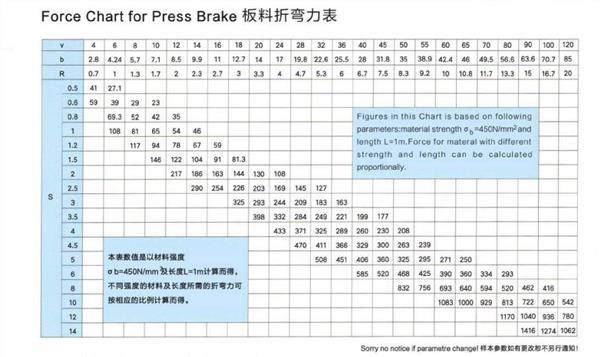

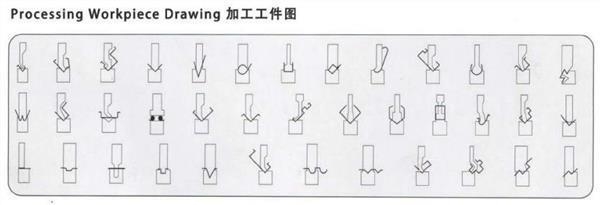

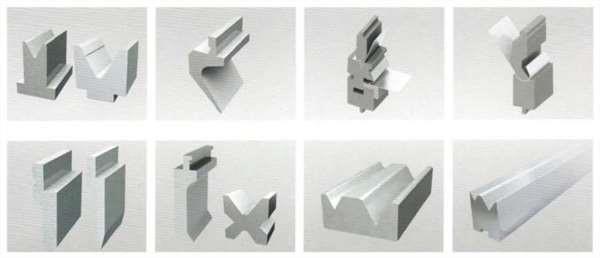

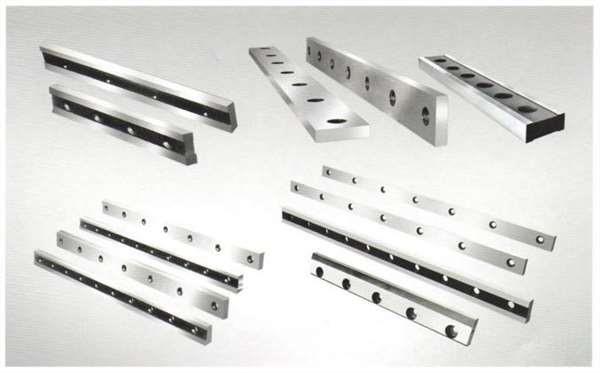

WC67Y series hydraulic metal plate bending machine/press brake blade diagram

WC67Y series hydraulic metal plate bending machine/press brake Technical parameters

型 号 | 公称压力 | 工作台长度 | 立柱间距 | 喉口深度 | 滑块行程 | 最大开启高度 | 主电机功率 | 外形尺寸 |

(KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

WC67Y- 40t/2200 | 400 | 2200 | 1775 | 250 | 100 | 320 | 5.5 | 2300×1500×2000 |

WC67Y- 40t/2500 | 400 | 2500 | 1975 | 250 | 100 | 320 | 5.5 | 2600×1500×2000 |

WC67Y- 63t/2500 | 630 | 2500 | 2095 | 250 | 120 | 360 | 5.5 | 2600×1600×2300 |

WC67Y- 63t/3200 | 630 | 3200 | 2570 | 250 | 120 | 360 | 5.5 | 3300×1600×2300 |

WC67Y- 80t/3200 | 800 | 3200 | 2565 | 320 | 120 | 360 | 7.5 | 3300×1700×2300 |

WC67Y- 80t/4000 | 800 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1700×2300 |

WC67Y- 100t/3200 | 1000 | 3200 | 2560 | 320 | 120 | 360 | 7.5 | 3300×1800×2400 |

WC67Y- 100t/4000 | 1000 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1800×2500 |

WC67Y- 125t/3200 | 1250 | 3200 | 2550 | 320 | 120 | 360 | 7.5 | 3250×1920×2450 |

WC67Y- 125t/4000 | 1250 | 4000 | 3450 | 320 | 120 | 360 | 7.5 | 4100×1920×2500 |

WC67Y- 160t/3200 | 1600 | 3200 | 2540 | 320 | 180 | 440 | 11 | 3300×1600×2600 |

WC67Y- 160t/4000 | 1600 | 4000 | 3140 | 320 | 180 | 440 | 11 | 4100×2000×2600 |

WC67Y- 160t/6000 | 1600 | 6000 | 4740 | 320 | 180 | 440 | 11 | 6100×2000×2600 |

WC67Y- 200t/3200 | 2000 | 3200 | 2540 | 320 | 250 | 530 | 11 | 3300×2100×2800 |

WC67Y- 200t/4000 | 2000 | 4000 | 3140 | 320 | 250 | 530 | 15 | 4100×2100×2900 |

WC67Y- 200t/5000 | 2500 | 5000 | 3120 | 400 | 250 | 530 | 15 | 5100×2100×3000 |

WC67Y- 250t/4000 | 2500 | 4000 | 3120 | 400 | 250 | 560 | 18.5 | 4100×2200×3500 |

WC67Y- 250t/5000 | 2500 | 5000 | 3920 | 400 | 250 | 560 | 18.5 | 5100×2200×3500 |

WC67Y- 250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

WC67Y- 300t/5000 | 3000 | 5000 | 39100 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

WC67Y- 300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

WC67Y- 300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

WC67Y- 350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

WC67Y- 350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

WC67Y- 400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

WC67Y- 400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

WC67Y- 500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

WC67Y- 500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

WC67Y- 500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

WC67Y- 600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

WC67Y- 600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

The parameters are for reference only, please add the QR code on the left for specific information and consult the staff.

FAQ

Q:Are you a manufacturer or a trading company?

A:We are a manufacturer; We specialize in metal sheet metal steel processing equipment.

Q:How to choose a bending machine/press brake?

A:Please tell us the following information in detail:

-Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model.

Q:How about the shipping fees for WC67Y series hydraulic metal plate bending machine/press brake?

A:The shipping cost depends on the way you choose to get the goods.Express is normally the most quickest but also most expensive way.By seafreight is the best solution for big amounts.Exactly freight rates we can only give you if we know the details of amount, weight and way.Please contact us for further information.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China