Bending machine

WC67K Series CNC Hydraulic Press Brake

WC67K series hydraulic servo CNC metal sheet bending machine/press brake Product introduction

The frame is integrally welded with steel plate, the appearance is appropriate and standard, and it has sufficient strength and rigidity.

Choose reliable electro-hydraulic proportional servo valve to synchronize organization.

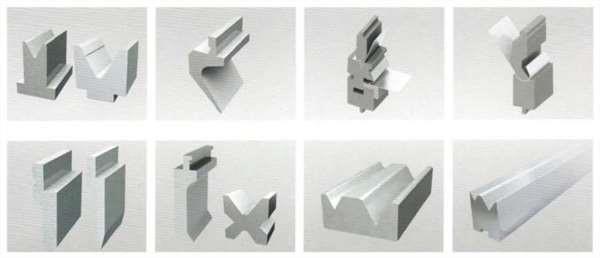

A standard set of upper and lower molds are randomly equipped (special molds can be provided according to the practical needs of users)

Optional Italian ESA/GV CNC system, which is a true CNC system for bending machines.

Complete functions, reliable performance, and very convenient to use. Give the office PC numerical control bending machine software together, so that the office computer and the bending machine numerical control system can communicate harmoniously.

Dutch DELEM CNC system and Italian ESA CNC system (optional according to customer's own needs)

(1) Number of control axes (3+1 axes) Y1, Y2 axis-slider up and down movement (electro-hydraulic servo valve) X axis-back gauge back and forth movement (servo motor) V axis-worktable plus convex

(2) Dutch DELEM CNC system

10.2 Two-dimensional colorful liquid crystal display

Two-dimensional graphics programming, direct programming and graphics programming can be completed on one page, and the bending process is actively programmed, and each step is simulated and displayed. Direct programming-directly input the scale and angle of each step; graphics programming-press the arrow keys to draw the workpiece graphics directly

Strong calculation ability and control ability, active correction ability-bending force-working table convex-large arc, blanking die-slider speed conversion point, pressing point, bottom dead point- Bending force, deflection compensation force, bending angle, pressing point, fast and slow speed conversion, complete active correction

The total step capacity is greater than 10,000

Data will not be lost when the power is cut off or shut down in the blink of a while, and the switch is fast

WC67K series hydraulic servo CNC metal sheet bending machine/press brake main configuration

Frame, cylinder, backgauge are supplied by professional factory

Electro-hydraulic proportional servo valve assembly — Germany HOERBIGER

CNC system — Dutch DELEM CNC system (optional according to customer's own requirements)

Servo motor (including encoder) — Yaskawa, Japan

Linear ruler — Italy GIVI

WC67K series hydraulic servo CNC metal sheet bending machine/press brake machine tool structure

a. Adopting all-steel welding frame, vibration aging treatment, with sufficient strength and rigidity.

b. Double oil cylinder control, mechanical block mechanism protection, hydraulic upper transmission, torsion shaft forced synchronization mechanism.

c. The stroke of the slider is quickly adjusted by electric, and there is manual fine adjustment, and the indicator shows

d. The upper die is equipped with a wedge-type deflection compensation mechanism to supplement the bending accuracy. Multi-machine linkage can be carried out (additional linkage synchronization device is required)

Specifications and models of WC67K series hydraulic servo CNC metal sheet bending machine/press brake:

型号 Type | 公称压力 | 工作台长度 | 立柱间距 | 喉口深度 | 滑块行程 | 最大开启高度 | 主电机功率 | 外形尺寸 |

Nominal Pressure | Worktable Length | Column spacing | Throat Depth | Slide Stroke | Max Open | Motor Power | Dimensions | |

(KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

WC67K-40t/2200 | 400 | 2200 | 1775 | 250 | 100 | 320 | 5.5 | 2300×1500×2000 |

WC67K-40t/2500 | 400 | 2500 | 1975 | 250 | 100 | 320 | 5.5 | 2600×1500×2000 |

WC67K-63t/2500 | 630 | 2500 | 2095 | 250 | 120 | 360 | 5.5 | 2600×1600×2300 |

WC67K-63t/3200 | 630 | 3200 | 2570 | 250 | 120 | 360 | 5.5 | 3300×1600×2300 |

WC67K-80t/3200 | 800 | 3200 | 2565 | 320 | 120 | 360 | 7.5 | 3300×1700×2300 |

WC67K-80t/4000 | 800 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1700×2300 |

WC67K-100t/3200 | 1000 | 3200 | 2560 | 320 | 120 | 360 | 7.5 | 3300×1800×2400 |

WC67K-100t/4000 | 1000 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1800×2500 |

WC67K-125t/3200 | 1250 | 3200 | 2550 | 320 | 120 | 360 | 7.5 | 3250×1920×2450 |

WC67K-125t/4000 | 1250 | 4000 | 3450 | 320 | 120 | 360 | 7.5 | 4100×1920×2500 |

WC67K-160t/3200 | 1600 | 3200 | 2540 | 320 | 180 | 440 | 11 | 3300×1600×2600 |

WC67K-160t/4000 | 1600 | 4000 | 3140 | 320 | 180 | 440 | 11 | 4100×2000×2600 |

WC67K-160t/6000 | 1600 | 6000 | 4740 | 320 | 180 | 440 | 11 | 6100×2000×2600 |

WC67K-200t/3200 | 2000 | 3200 | 2540 | 320 | 250 | 530 | 11 | 3300×2100×2800 |

WC67K-200t/4000 | 2000 | 4000 | 3140 | 320 | 250 | 530 | 15 | 4100×2100×2900 |

WC67K-200t/5000 | 2500 | 5000 | 3120 | 400 | 250 | 530 | 15 | 5100×2100×3000 |

WC67K-250t/4000 | 2500 | 4000 | 3120 | 400 | 250 | 560 | 18.5 | 4100×2200×3500 |

WC67K-250t/5000 | 2500 | 5000 | 3920 | 400 | 250 | 560 | 18.5 | 5100×2200×3500 |

WC67K-250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

WC67K-300t/5000 | 3000 | 5000 | 3910 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

WC67K-300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

WC67K-300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

WC67K-350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

WC67K-350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

WC67K-400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

WC67K-400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

WC67K-500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

WC67K-500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

WC67K-500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

WC67K-600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

WC67K-600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

FAQ

Q:Are you a manufacturer or a trading company?

A:We are a manufacturer,We specialize in metal sheet metal steel processing equipment with more than 12 years of technology and experience.

Q:How to choose WC67K series hydraulic servo CNC metal sheet bending machine/press brake?

A:Please tell us the following information in detail:

-Material of plate:

-Max thickness:

-Max plate width:

Q:What certificate the machine in your company get for WC67K series hydraulic servo CNC metal sheet bending machine/press brake?

A:We've passed the ISO9001 Quality System Approval and CE Certification.

Q:What is your terms of payment?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q:How about the shipping fees for WC67K series hydraulic servo CNC metal sheet bending machine/press brake?

A:The shipping cost depends on the way you choose to get the goods.Express is normally the most quickest but also most expensive way.By seafreight is the best solution for big amounts.Exactly freight rates we can only give you if we know the details of amount, weight and way.Please contact us for further information.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China