Hydraulic press

Frame Type Hydraulic Press for Doors: Anti-Theft, Steel-Wood, Interior

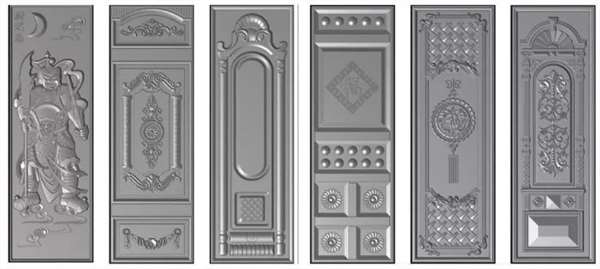

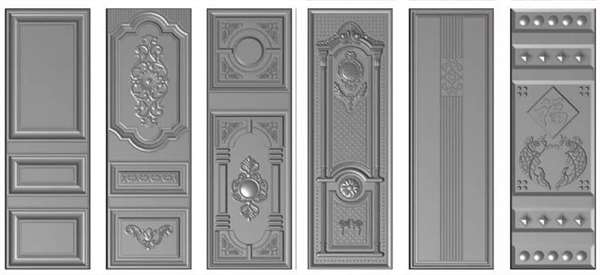

Frame type hydraulic press machine for anti-theft doors, steel-wood doors, interior doors is a special hydraulic press for forming anti-theft doors, steel-wood doors, and interior doors. It is also suitable for pressing, bending, flanging, extrusion and other processes of plastic materials. It can also be engaged in correction, pressing, and pressing and forming of powder products. Non-metallic materials such as plastics, glass fiber reinforced plastics, insulating materials and abrasive products are press-formed. This model is suitable for deep drawing, anti-convex and other processing techniques, and can highlight the three-dimensional effect of the workpiece.

Product detail presentation

Host part

The overall structure of the fuselage adopts steel plate welding structure, and the welding adopts carbon dioxide gas shielded welding to eliminate internal stress points after welding.

Main cylinder

The cylinder body of the cylinder is made of carbon steel forgings, and the cylinder bore and rolling hardness after processing

Hydraulic system

The hydraulic system is mainly composed of oil pump, valve block, filling valve, cooling filter system, pipeline, etc. The electrical control system controls various actions of the hydraulic machine.

Electrical control system

The electrical components adopt domestic products or according to customer requirements

Equipment usage conditions:

1. Equipment working area temperature: -20~60℃ (±)

2. Power supply: three-phase four-wire system 380V, 50HZ, voltage fluctuation range 380V±10%

3. Cooling method: water cooling device

4. The medium used in the hydraulic system: No. 46 anti-wear hydraulic oil.

Performance characteristics of Frame type hydraulic press machine for anti-theft doors, steel-wood doors, interior doors:

Frame structure, good rigidity; high precision; four-column structure is simple, economical and practical.

The hydraulic control adopts a cartridge valve integrated system, which has small impact, reliable action, long service life and few leakage points.

The new type oil cylinder sealing element has high reliability and long life.

Stretching and blank-holding sliders can be connected as a whole to realize single-action process.

The lifting and closing speed is adjustable, accurate and reliable.

Two-hand operation, safe, efficient and reliable, operation mode: adjustment, manual, semi-automatic three operation modes

Fast profiling and pressing, also available for no-load fast profiling and slow compression

Control mode: two kinds of constant pressure suppression and constant process suppression.

FAQ

We are factory, and was set up in 2009! Our factory mainly production shearing machine, press brake machine, rolling machine, punching machine, hydraulic press machine ,iron worker, welding machine.

Guarantee period:

Our product quality guarantee period is 12 months from B/L date.During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us.If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price.We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation.In turn, your engineers can come to our factory for learning the installation,operation and maintenance for free.

Why Choose Us:

1.We will run the machine for a few days, and use your materials to do the test.Only guarantee the machine shows best

performance, and then we will ship out.

2.Our elite teams can provide you professional, customized, and all-round services around the clock.If you need any help,contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1.Gather your requirements based on your real working situation.

2.Analyze your information and provide our feedback.

3.Offer options based on your specific needs.For instance, reg.standard products, we can offer professional recommendations;reg.non-standard products, we can offer professional designing.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China