Polisher machine

Polishing machine of stainless steel tank production line

Polishing machine of stainless steel tank production line

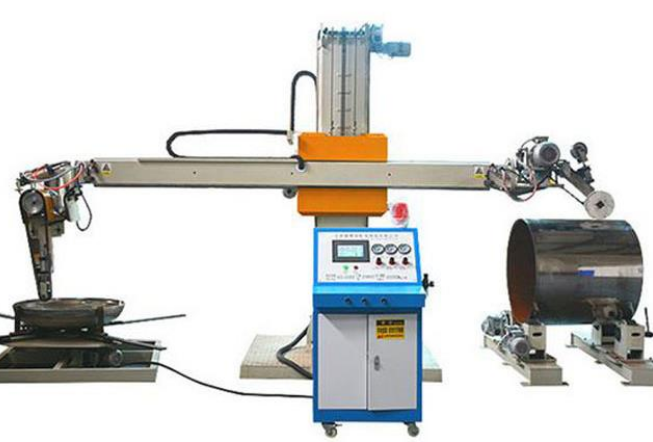

Polishing machine of stainless steel tank production line Equipment overview:

The Polishing machine is a machine tool specially used for rough grinding, fine grinding, wire drawing and mirror polishing of various industrial can bodies, inner and outer surfaces, longitudinal and circumferential welds. Different types of grinding heads can be designed according to requirements, and various stainless steel products can be ground and polished using abrasive belts, thousand impeller wheels, fiber wheels, hemp wheels, etc.

Application scope of Polishing machine of stainless steel tank production line:

The equipment is mainly used in chemical, food, biological, water treatment, pharmaceutical, printing and dyeing, pressure vessel and other fields.

1. Medical disinfection cabinet, filter

2. Various cylinder blocks and cylinder heads

3. Inside and outside welds at the end of various large conveying pipes

4. Various oval heads, butterfly heads, conical heads, spherical heads, flat heads

5. The inner and outer surfaces of nuclear reactors and similar high-pressure heavy vessels have been polished and polished

Technical parameters of Polishing machine of stainless steel tank production line:

Abrasive belt specifications (width × circumference): 50 * 1880mm (adjustable according to the structure of the grinding head)

Diameter range of processing head: 500-3200mm (can be customized according to customer's products)

The surface roughness of the processed workpiece Ra: ≤0.1um (specific requirements can be met by multiple grinding, depending on the process)

The fuel tank cap integrated machine is introduced in detail

Machine principle of Polishing machine

The surface roughness of the workpiece can be improved by grinding and polishing the inner and outer surfaces and welding seams of the cylinder through the friction between the abrasive belt or the 1000 impeller and the surface of the workpiece.

The structure of the machine tool of the Polishing machine of stainless steel tank production line

It consists of a mechanical part and an electrical control part.

The mechanical part is composed of a polishing system, a polishing wheel walking system and a workpiece turning table.

The main structure is a welded structure.

The electrical control part is composed of control cabinet, frequency converter and electric motor.

Polishing machine of stainless steel tank production line Structure description

The whole process of pneumatic floating tracking grinding head technology is adopted to uniformly polish and polish the inner and outer surfaces of the tank.

The beam can be steplessly adjusted up and down, left and right, and workpiece rotation.

The angle of the grinding head can be changed, that is, it can be rotated 90 degrees, which can meet the longitudinal and circular polishing methods;

The main parameters of the Polishing machine of stainless steel tank production line are as follows:

1. Equipment dimensions (length×width×height): 5500×1600×3100mm

2. Total mass of equipment: 2200KG

3. Surface roughness Ra≤0.4m (select and sequentially achieve polishing materials with different mesh numbers)

4. Suitable for polishing materials: abrasive belt, 1000 impeller, cloth wheel

5. Total input power: about 9.8KW

As one of the professional Water tank/Oil tank/Fuel tank production line machines/equipments, this product plays a very important role. If you want to know more about the Water tank/Oil tank/Fuel tank production line machines/equipments, you can click to view the details, or contact us directly.

CATEGORIES

- Kitchen sink/wash basin production line machines and equipments

- Wheelbarrow/trolley production line machines and equipment

- Aluminum foil food container production line machines and equipment

- JCO pipe production line machines/equipments

- Light pole/power pole/communication tower pole production line machines and equipments

- Water tank/Oil tank/Fuel tank production line machines/equipments

- Pressure vessel production line machines/equipments

- LPG gas tank/cylinder production line machines/equipments

- Sieve production line machines/equipments

- Electric water heater production line machines and equipments

- H-beam profile production line machines and equipments

- Steel door production line machines and equipments

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China