JCO pipe production line machines/equipments

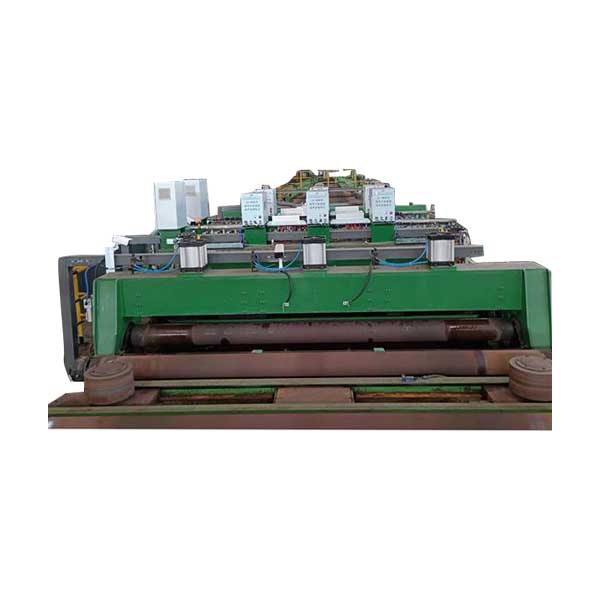

Ultrasonic flaw detector pipe inspection system

Ultrasonic flaw detector pipe inspection system of jco/jcoe/lsaw pipe production line Flaw detection process

Magnetic crane puts the steel plate on the roller table → PLC controls to drive the steel plate to the flaw detection area → steel plate centering → start the steel plate forward → steel plate pre-wetting → 150mm 100% flaw detection at the steel plate head → 80mm 100% flaw detection at the edge of the steel plate → 100% flaw detection in the middle comb → 150mm 100% flaw detection at the tail of the steel plate → wipe, air dry → discharge → end of the flaw detection process → wait for the next cycle.

Ultrasonic flaw detector pipe inspection system of jco/jcoe/lsaw pipe production line composition and function

Dedusting and rust removal device for steel plate: before the inspection, the surface of the steel plate is cleaned by removing rust and dust.

Follow-line drag chain: Various cables and control lines required by the equipment adopt chain rail type engineering plastic drag chains with protective plates, which greatly protects various cables and can shield various harmful interferences.

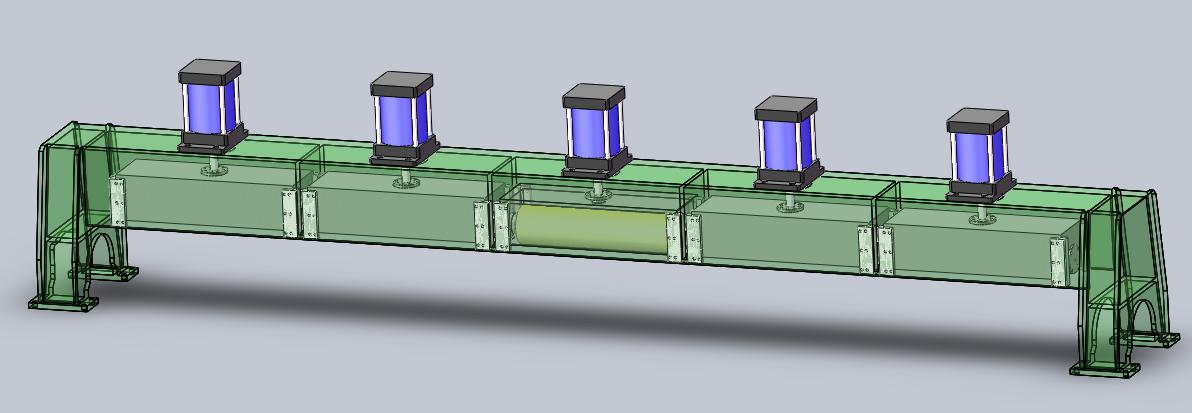

Pre-wetting device: Pre-wet the surface of the steel plate to ensure the coupling of flaw detection.

Pressure rollers: There are two groups of pressure rollers before and after the probe frame to increase the stability of the steel plate, make the steel plate and the probe better coupled, and prevent the steel plate from affecting the flaw detection effect due to beating.

Ultrasonic flaw detector pipe inspection system of jco/jcoe/lsaw pipe production line Control process description

(roller table in flaw detection area, front and rear roller table drive device, frequency converter, detection element and control cable shall be provided by the buyer, and the control and operation shall be the responsibility of the seller)

The steel plate is transported by the roller table to the front of the inspection area→PLC control drives the steel plate to the inspection area→the centering of the steel plate is completed→start the steel plate to move forward→the steel plate end sensor detects the steel plate head→the steel plate is pre-wetted, and the front pressing roller is based on the steel plate head. The position falls → the steel plate advances to the head and tail detection area and stops, and the 150mm 100% flaw detection of the steel plate head is carried out → the rear pressure roller falls according to the position of the steel plate head → the steel plate advances to the edge flaw detection area, and the steel plate edge is 80mm for 100% flaw detection → the steel plate advances to In the central flaw detection area, the probe in the middle is dropped for comb-like 100% flaw detection → according to the position of the head of the steel plate, the air drying frame is dropped, the fan is started → the end of the steel plate is detected by the sensor at the end of the steel plate → the pre-wetting stops, and the front pressure roller rises according to the position of the end of the steel plate. Lifting → The steel plate advances to the head and tail detection area and stops, and the 150mm 100% flaw detection of the steel plate tail is carried out → The rear pressure roller is raised according to the position of the steel plate tail → The side inspection stops and returns to the original position → According to the position of the steel plate tail, the middle probe is raised → And the head, tail and both sides of the flaw detection → According to the position of the steel plate tail, the air drying frame is raised, the fan is stopped → the material is discharged → the flaw detection process is over → wait for the next cycle.

As one of the professional JCO pipe production line machines/equipments, this product plays a very important role. If you want to know more about JCO pipe production line machines/equipments, you can click to view the details, or contact us directly.

CATEGORIES

- Kitchen sink/wash basin production line machines and equipments

- Wheelbarrow/trolley production line machines and equipment

- Aluminum foil food container production line machines and equipment

- JCO pipe production line machines/equipments

- Light pole/power pole/communication tower pole production line machines and equipments

- Water tank/Oil tank/Fuel tank production line machines/equipments

- Pressure vessel production line machines/equipments

- LPG gas tank/cylinder production line machines/equipments

- Sieve production line machines/equipments

- Electric water heater production line machines and equipments

- H-beam profile production line machines and equipments

- Steel door production line machines and equipments

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China