Production line

Handmade sink production line

Handmade Sink Production Procedure and Equipment Solution Description

The main equipment list

Cutting Machine

Press Brake/Bending Machine

Welding Equipment

Surface Treatment Equipment

All products can be purchased as a set or individually. For specific information, please contact us directly and we will reply as soon as possible.

Handmade sink production line machines and equipments Solution Description

A. The metal sheets are cut accurately according to the design requirements to form the basic shape of the sink.

B. Punch presses punch holes, grooves, and shapes into metal sheets.

C. The bending machine bends the cut metal plate into the shape of the sink according to the design requirements.

D. Weld the different parts of the sink together.

E. Sink surface treatment.

F. Stamp and cut drain holes by press machine.

G. Testing and packaging.

Cutting Machine

Cutting equipment is one of the key components of a sink production line. It includes various types of cutting machines, such as laser cutting machines, plasma cutting machines, etc. These machines are used to accurately cut sheet metal into the basic shape of the sink according to the design requirements.

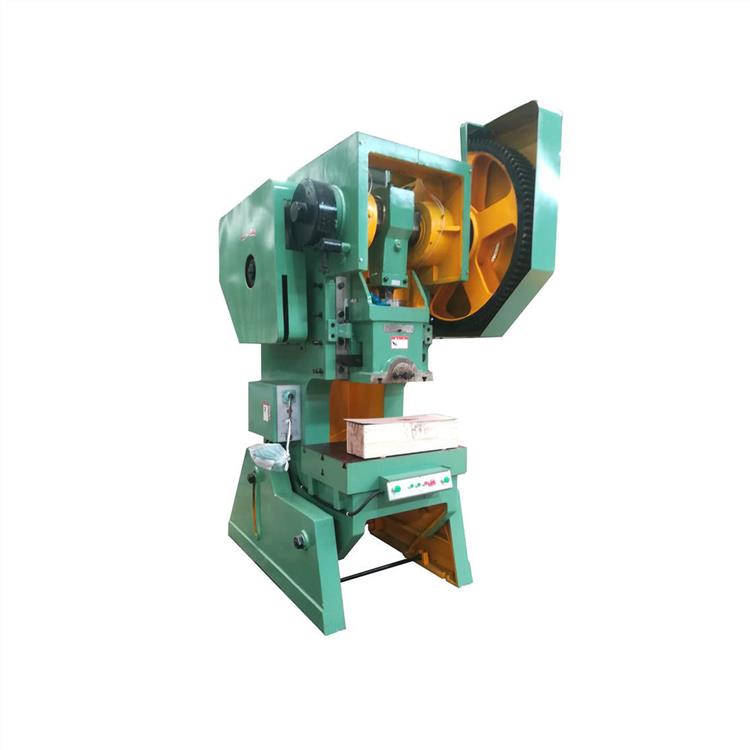

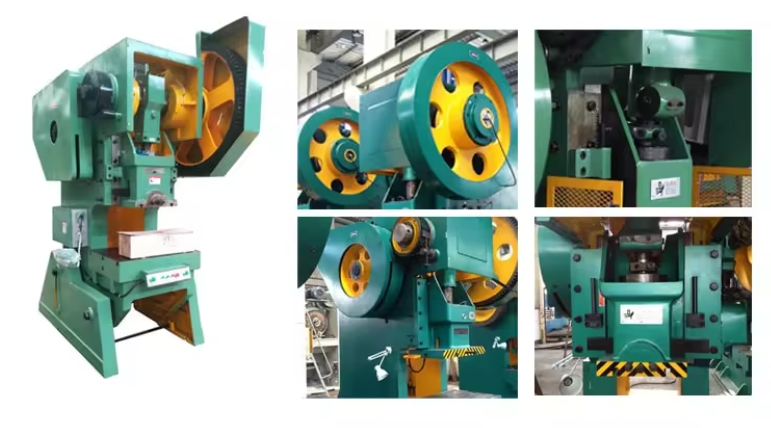

Punching Press Machine

Punch presses are used to punch out various holes, grooves, and shapes in metal sheets. These holes and grooves are used not only for the sink's appearance but also for drainage and mounting of accessories. The higher the degree of automation of the punch press, the higher the production efficiency, so the automation level of the equipment needs to be considered when selecting.

Press Brake/Bending Machine

The bending machine is used to bend the cut metal plate into the shape of the sink according to the design requirements. It enables accurate bending angles and bending radii to ensure that the geometry and dimensions of the sink comply with standards. Bending machines usually have CNC functions, making operation more precise and convenient.

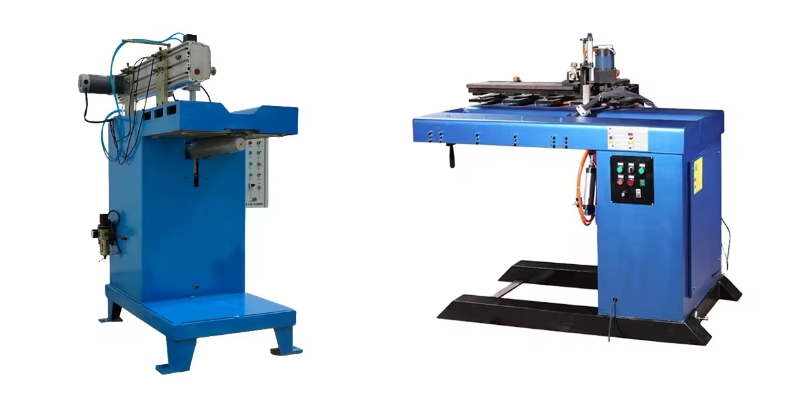

Welding Equipment

The assembly and connection of sinks often require welding skills. Welding equipment includes welding robots, gas shielded welding machines, etc., used to weld different parts of the sink together. Automated welding systems can improve welding quality and efficiency while reducing the need for manual operations.

Surface Treatment Equipment

The surface treatment of your sink is critical to improving appearance quality and corrosion resistance. Surface treatment equipment includes sandblasting machines, polishing machines, etc., which are used to clean the surface, remove rust, improve gloss, etc. These equipment ensure that the sinks produced meet the customer's needs in both appearance and performance.

Jiuying production line list

Aluminum foil box/container production line machines/equipments

Water tank/Oil tank/Fuel tank production line machines/equipments

Solar/electric water heater production line machines/equipments

If you have other production line requirements, you can also contact us directly for consultation.

FAQ

Q1:What materials are used in your handmade welded sinks?

A: Our handmade welded sinks are primarily crafted from high-quality stainless steel. Stainless steel offers durability, resistance to corrosion, and easy maintenance, making it an ideal material for kitchen sinks.

Q2:Can the size and shape of the sink be customized?

A: Yes, we offer customization options for our handmade welded sinks. Customers can specify their desired dimensions and shape, allowing us to tailor the sink to fit their kitchen space and design preferences.

Q3:Are your welded sinks suitable for commercial use?

A: Our handmade welded sinks are designed to meet the demands of both residential and commercial settings. They offer durability, functionality, and a sleek appearance, making them suitable for use in restaurants, hotels, and other commercial establishments.

Q4:How to choose the kitchen sink production line? How can we get more detailed information?

A: Plz give us your design drawing and the budget invest of the kitchen sink, our kitchen sink production line manager will make solution according these information. Our kitchen sink production line manager

contact information: mail:liu@weldcnc.com,whatsapp/wechat:008613394110095

Q5:How about the machine warranty time? Is the complete production line?

A: We provide 2 years warranty for the machines of the kitchen sink production line. we can supply the whole kitchen sink production line if you need. and can supply the kitchen sink production line machines separate also.

CATEGORIES

- Kitchen sink/wash basin production line machines and equipments

- Wheelbarrow/trolley production line machines and equipment

- Aluminum foil food container production line machines and equipment

- JCO pipe production line machines/equipments

- Light pole/power pole/communication tower pole production line machines and equipments

- Water tank/Oil tank/Fuel tank production line machines/equipments

- Pressure vessel production line machines/equipments

- LPG gas tank/cylinder production line machines/equipments

- Sieve production line machines/equipments

- Electric water heater production line machines and equipments

- H-beam profile production line machines and equipments

- Steel door production line machines and equipments

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China